As featured in waterline Winter 2020-21

FINER AND FINEST

– FILTRATION FOR SWIMMING WATER

by Michael Cormacey, MISPE, SAC, Dip(Eco-Bldg.Design) MWM.Soc., M.D. Aqua Blue Designs

Water filtration, whether in balneology or in the field of effluent and waste water treatment, relies on the same basic principles. Filtration in both swimming pools and sewage plants can be described as removing the visible debris and particles which would otherwise create an environment for bacteria and micro-organisms to flourish.

We take much of this for granted in our domestic water supply. This removal of pollutants was brought home to me vividly on a recent holiday to Devon in a motorhome, when we had to deal with our own waste grey water and foul water, which required the removal and emptying by hand of what was euphemistically referred to as a ‘cassette’. The last cassette I used was something with Abba on it! Every few days the cassette had to be removed from the vehicle and emptied to a foul drain and the filtration, of course, happened some miles away at what we call the ‘sewage farm’ and the French call a purification farm, which I prefer. In pool filtration and sewage treatment, sand is a key element in removal of unwanted matter, usually by gravity in the latter case.

The idea of water being filtered through sand and gravel to improve its quality was known to the ancient civilisations of the Middle East in the context of finding and maintaining healthy drinking water in areas where at times, it could be in short supply.

The Greeks also valued clean water and produced a primitive filter consisting of a cloth sleeve for small scale use. The Romans prized clean water for both hygiene, leisure and religious reasons and made sure they had adequate supplies of it. Maintaining water quality was simple. Fresh water displaced the contaminated water and where there were hot natural springs at a constant temperature, as at Aquae Sulis they had a plentiful supply of fresh hot water.

Unless there was such a geo-thermal source, water had to be heated by burning fossil fuels and so it became more necessary to retain it.

In the 17th century, Sir Francis Bacon was a pioneer of a scientific experimental approach to water filtration and the Italian physician Lucas Antonio Portius experimented with primitive sand filters.

In Scotland in 1804 the first documented use of a sand filter in industry was recorded when John Gibb invented one for use in his bleachery and the surplus water was sold to the public locally. The first public treated waterworks was in London in 1829 and utilised the same principles.

In Victorian and Edwardian times, swimming pools and lidos became popular as recreation for the masses. Initially filtration was not needed as these pools utilised water from rivers or from the sea; a constant source of freshwater, so were mainly for summer use. The heyday of the outdoor lido was in the first half of the 20th Century and this was when sand filters were added to improve water quality.

As this is not intended to be a concise history of swimming pools, I focus on the methods of filtration used after we started building purpose designed indoor swimming pools, leisure centres and competition pools.

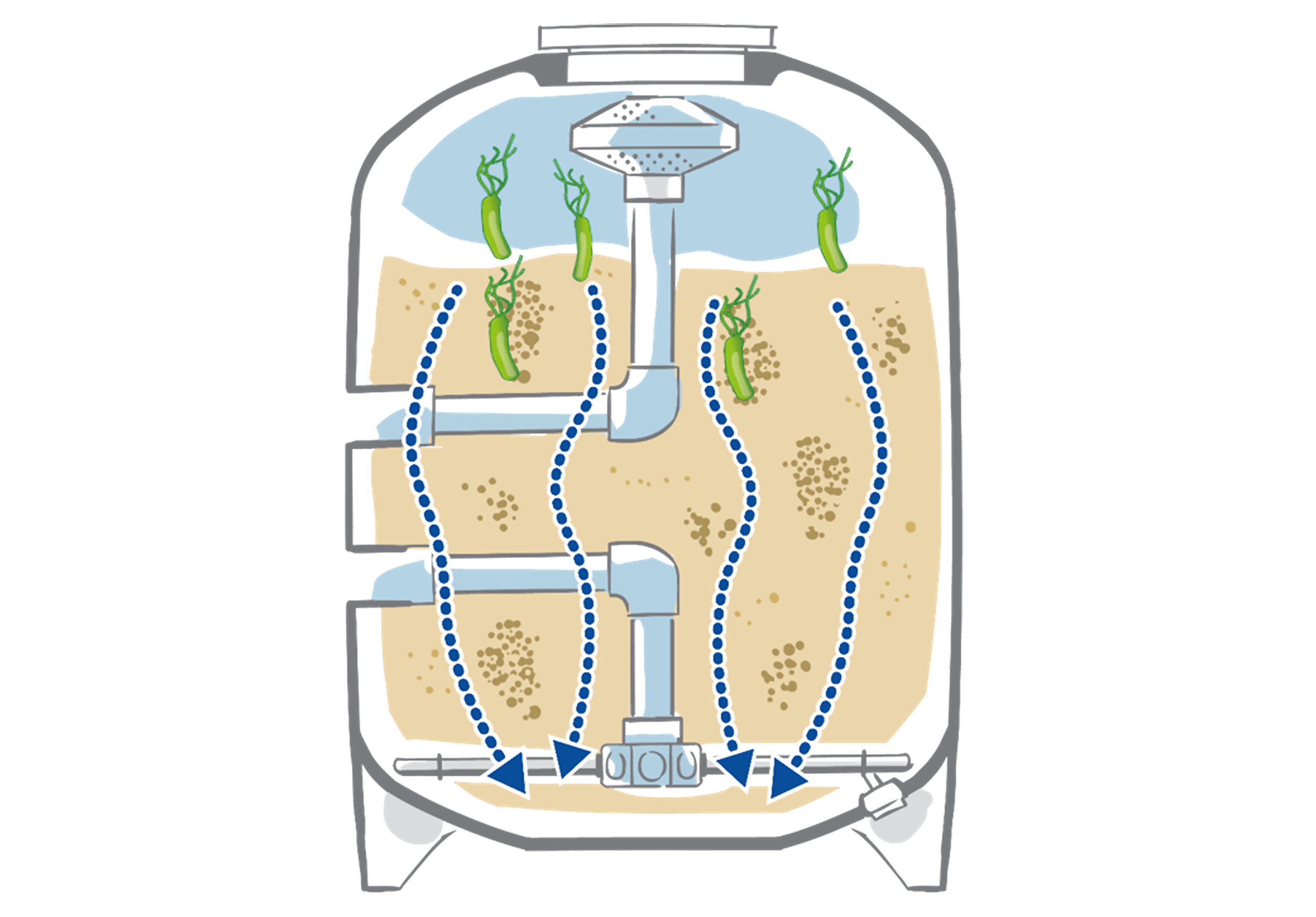

Banks of filters became the norm which continued to utilise the ancient principles of sand, but the water was now pumped through the medium under pressure and was sanitized with chlorine and heated. There was a need more than ever to conserve the heated and chemicalized water. Sand filters basically trap the particles of matter upon which bacteria etc thrive. The process is reversed frequently to release the trapped matter from the sand bed and pump it to waste. This water needs to be replaced and only in this respect, we continue in the old way of discarding pollutants.

There are standards governing the filtration processes, set by PWTAG, H & S Executive and SPATA which apply to commercial pools, where frequent backwashing and dilution of 30 litres/bather/day of fresh water is required. In domestic pools, the standards are less stringent, but backwashing is still necessary. Now it is logical that lower filtration is generally more effective than the opposite and the rate at which water passes through the medium is crucial. This is also set out in PWTAG and SPATA standards, expressed as a combination of the flow rate and the filter bed area in m3/m2/per hour. Commercial pools require slower filtration – below 25m3/m2/hr known as medium rate and domestic pools, usually but not necessarily, between 25 and 50m3/m2/hr known as high rate. (Some municipal pools have in the past used slow rates below 10m3/m2/hr i.e. but this is rare.)

Sand filters for all their worth are not very fine filters and often need the help of flocculants to coat the incoming particles and make them large enough to be trapped by the sand. Chemicals such as poly-aluminium chloride have been used for this purpose, to stop the fine debris being sent straight back to the pool again. The rate of backwashing is critical if all the accumulated debris is to be discarded to waste and this is calculated to suit each pool.

Sand filters range in size from small domestic filters at 0.40m dia. to commercial filters at 3m dia. x 3m high with a 1.2m deep sand bed, some with gravel of different grades beneath the sand. There are also deep bed filters and pre-filters available to augment the sand filter’s performance in different applications.

After backwashing for 4 or 5 minutes, the rinse mode is activated to settle the medium down again, after the turbulence of this operation.

Alternative methods of filtration, which have been used in the pool industry are cartridge filters, where a cartridge element must be removed and scrubbed clean frequently before being reused – often sold in combination with domestic spa baths. Another less popular system is the diatomaceous earth filter, which consists of veins in the filter chamber which must be coated in the said diatomaceous powder to trap the debris. Both of the last two mentioned methods will filter finer than sand. Despite this, for most of the history of the wet leisure industry, sand has ruled as the medium of choice. However, in the last two decades some significant challengers have arrived on the scene.

Zeolite was the first serious contender as an alternative filter medium. It is a microporous mineral mined in Africa. It has a high capacity to remove ammonia and greatly reduces turbidity. Its natural very porous structure means it filters finer than sand, improves clarity and with catalytic qualities is rated in the trade as a 60% superior medium and has the surface capacity to last considerably longer than sand before needing to be replaced or regenerated.

Glass and quartz have been used in various forms through the 20th Century, but in the last decade it’s refined glass which has come to the fore as a superior medium in this industry. However, there are various sources of variable quality. The very best conform to the EU standard CEN/TC164/WG9. AFM is the result of a revolutionary, 21st century approach to the whole subject of pool filtration and has produced remarkable results and solves some of the failings of sand and other media by preventing biofilms.

AFM

Sand filters are very much the technology of the last century. They allow bacteria to form colonies, mud-balling in clumps of sand. Anoxic zones protected by a biofilm, are created leading to channelling of the water through the bed as it seeks the line of least resistance. This allows unfiltered water to pass right through the filter and back to the pool, complete with all the unwanted particles and contaminants. The latest superior glass medium prevents this biofilm forming and massively improves the performance of the filter.

Mud-Balling Filter

A sand filter will trap material down to approximately 10 microns at best. The very best glass medium will filter down to 1.0 microns, removing 95% of these particles in one pass and with the addition of an advanced coagulation and flocculation system, can filter down to 0.1 microns, producing pool water of drinking water quality and of high clarity for swimming in! This also reduces all the unpleasant odours caused by chlorine by-products, chloramines and trichloramines. Less frequent backwashing is needed, saving up to 50% wasted water. With this high-performance AFM glass, chlorine demand can be reduced by up to 80% in some cases and at the same time the risk of Legionella is reduced, along with stubborn microorganisms like Pseudomonas and cryptosporidium. This medium really is the finest. AFM is now tried and tested on many commercial pools and represents a giant step forward for ‘pool man & woman’.

OC-1 is another radical new approach to filtration, inasmuch as it relies on many plastic mouldings and a settlement technique to collect particles as opposed to trapping them in normal media. It means that pressures do not build-up in the filter rapidly. Pump speeds can be reduced, saving electricity and backwash times can be extended by several times, saving on water loss and associated costs of heating and chemicals.

OC-1

This product does not need to be replaced every 4 years like sand and as it creates a constant flow, eliminates the heater cut-out problem caused by frequent pressure build-up in sand filters. A leisure centre in Australia reported a saving on wasted water of over 1 million litres in one year using the OC-1 medium.

In recent years we have made real progress, via improved filtration media in improving water quality in swimming pools and conserving this valuable resource – water. Watch this space for some of these improvements becoming the new norms. We’ll soon be able to make pool water so clear, you won’t be able to see it!

St David’s Holiday Park Swimming Pool

Image courtesy of Panorama Studios

Designed by Aqua Blue Designs