As featured in Waterline Spring 2021

Going Off-Grid – The Decentralised Production of Point-of-Use Drinking Water

by Gillian E Clayton2, Tapan K Dutta1, Bethany G Fox2, Robin M S Thorn2 and Darren M Reynolds2

1 Department of Microbiology, Centenary Campus, Bose Institute, Kolkata

2 Centre for Research in Biosciences, Faculty of Health and Applied Sciences,

University of the West of England, Bristol

Safe water is essential for human life and it is essential if individuals, families and communities are to thrive and develop. In an increasingly stressed and damaged world, more people now have access to safe water than at any other time since the industrial revolution. The Sustainable Development Goals, have helped increase the provision of safely managed drinking water (World Health Organization and UNICEF, 2017) sources to communities around the world from 61.25% in 2000 to 70.64% in 2017 (World Bank, 2020). Despite this progress, it is estimated that over 2 billion people still lack water security and access to a safely managed drinking water source (United Nations, 2020). The centralised provision of safe water via large infrastructure and further urban development is still seen as the main solution but this presents significant social and economic challenges for many low and low-middle income countries. There are some scientists who now advocate a fundamental shift from the way we provide high-quality drinking water at present, advocating a move away from large-scale centralised provision to smaller-scale decentralised, (off-grid) water production and delivery.

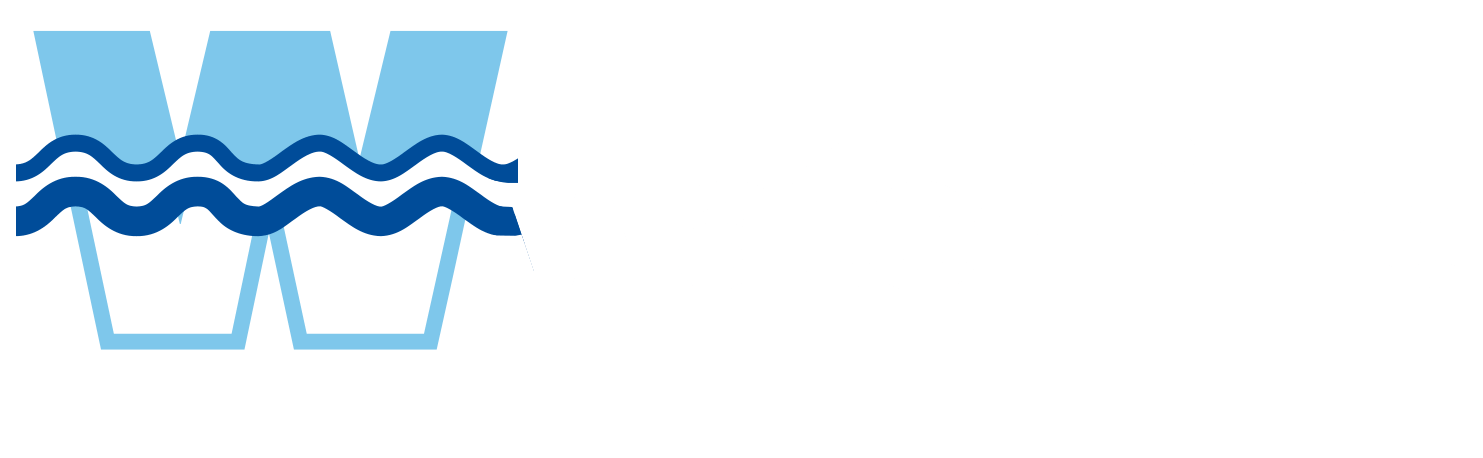

In the autumn of 2015 we reported in waterline a rudimentary system for the off-grid production of drinking water that was housed in a small garden shed (Reynolds et al., 2015). Six years on, in partnership with UK industry (Portsmouth Aqua Ltd), we have now fully tested and developed a minimum viable product for the continuous decentralised production of drinking water that is compliant with European drinking water standards. The original concept reported in waterline in 2015 described a self-contained and easily transportable system, that is relatively inexpensive requiring only minimal maintenance and can be rapidly deployed. Importantly, the system is designed to be adaptable for off-grid operation. To enable continuous operation and provide safe water the on-demand production of a disinfectant is essential. Our system utilises “electrochemically activated solutions” produced via a commercial electrochemical cell as a disinfectant. Electrochemically activated solutions help minimise the formation of biofilms by pre-ultrafiltration [UF] membrane dosing and also disinfectant the produced water (Clayton, Thorn and Reynolds, 2019b). ECAS are produced via the electrolysis of a low mineral salt solution (the electrolyte) in an electrochemical cell (Figure 1). When a direct current is applied, electrochemical processes at the material electrode surface transform the electrolyte (NaCl) into an activated “metastable” state, exhibiting elevated chemical reactivity and resulting in the modification of molecular and ionic structures. Substances produced at the anode are known to be active against a broad spectrum of microorganisms (Robinson et al., 2010) and have been evaluated extensively within the health and food sectors, particularly in relation to decontamination (Thorn et al., 2012). The electrolytic production of ECAS can be performed on-demand requiring only salt (NaCl), a small volume of water and electricity. On-site production of a disinfectant obviates the need for the transport and storage of large volumes of liquid disinfectant, thereby reducing the associated environmental impacts associated with this. ECAS are widely considered to be environmentally friendly, fulfilling the role of a “green biocide” through reduced free chlorine use and a reduction in the requirement for disposal of toxic chemicals. Such electrochemical systems can now be designed to produce stabilised hypochlorous acid which is recommended as an emergency disinfectant by the World Health Organisation and exhibits very low toxicity to both humans and the environment (Robinson, Thorn and Reynolds, 2013; Clasen and Edmondson, 2006). Importantly, recent research has shown that the use of ECAS and/or hypochlorous acid for water disinfection reduces the production and occurrence of disinfection by-products when compared with the use of hypochlorite solution (Clayton, Thorn and Reynolds, 2019a).

Figure 1. Schematic showing an electrochemical cell used for generating electrochemical activated solutions (ECAS) and or hypochlorous acid (HOCl), comprising of two electrodes, an anode (+) and a cathode (-), separated by an ion-permeable exchange diaphragm. During operation, a salt solution is continuously perfused into both the anodic and cathodic chambers. The main general chemical reactions thought to occur at each electrode when a unipolar direct current is applied, with additional chemical transformations being dependent on the nature of the electrode material and specific electrolyte used. Figure taken from Clayton, Thorn and Reynolds, 2019a.

Upscaling from proof-of-concept to PAqua 1000D-2

The proof-of-concept small-scale decentralised drinking water treatment system first reported in 2015 (Waterline 2015), was built in a steel shed (3.15m x 3.35m) located on the banks of a modified artificial water body at the University of the West of England, Bristol (See figure 2).

Figure 2. The modified artificial water body located at the University of the West of England, Bristol (top) and the water purification system, housed in a steel shed (3.15m x 3.35m).

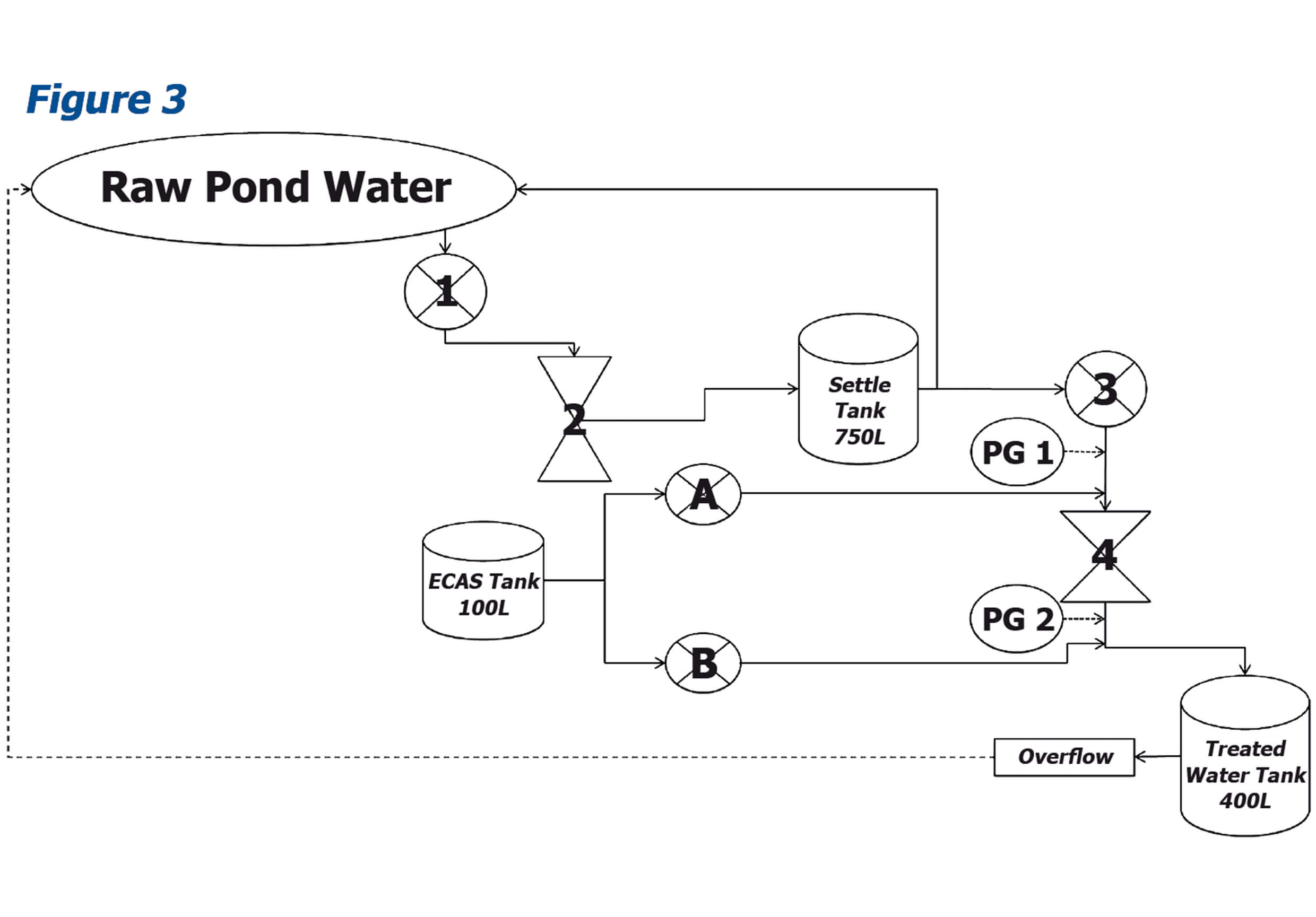

The small-scale proof-of concept system pumped raw water from a large modified artificial water body through a 100-micron reverse rinsing filter and into a 750L holding tank. Although this can achieve good water purification, it is not 100% effective at disinfection and achieved up to 98% removal of all viruses and bacteria that may be present in the source water. An additional complication of this arrangement was biofilm formation in the UF membranes which occurs over time, this results in fouling and blockages, limiting the longevity of the system and impacting on performance. ECAS exhibits much higher antimicrobial efficacy (x100) at equivalent free available chlorine concentrations than other more conventional chlorine releasing compounds such as hypochlorite for example. Hypochlorous acid (HOCl) is the main active chlorine species in electrochemically activated solutions where the pH of these can be controlled and maintained between 6 and 7. This is an important feature, since free chlorine in the form of dissolved chorine gas or hypochlorite can cause oxidation damage to filtration membranes, in our system the application of ECAS/HOCl pre and post-UF membrane enables the inhibition of biofilm formation, whilst achieving total disinfection, allowing for continuous operation. A schematic showing the design of the proof-of-concept drinking water treatment system is shown in Figure 3. At various stages of treatment samples can be routinely tested for chemical and microbiological quality.

Figure 3. Basic schematic of the proof-of-concept off-grid drinking water production system. Direction of arrows refer to water flow direction. (1) Submersible filter pump (115 μm); (2) Reverse flushing filter (100 μm); (3) Peristaltic pump; (4) UF membrane columns (0.02 μm); ECAS reservoir tank 100L for ECAS generated outside of the DWPS; (A) & (B) ECAS peristaltic dosing pumps for delivering ECAS into the bulk treated water stream; (PG) Pressure gauges. Figure reproduced from Clayton, Thorn & Reynolds, 2019b under licence number 5025820521674.

The proof-of-concept decentralised drinking water treatment system has been developed by Portsmouth Aqua Ltd and UWE, Bristol. The PAqua 1000D-2 has an increased capacity with the ability to produce to 1000 L per hour of drinking water to EU standards. Trials conducted at UWE Bristol, using the same modified water body as in 2015, has been conducted on the PAqua 1000D-2. Flow rates ranging between 300 and 700 L per hour have been systematically tested, and have shown that high quality drinking water can be consistently produced from the polluted water body (see table 1). The PAqua 1000D-2 unit located on UWE Bristol’s Frenchay campus has produced in excess of 6 million litres of drinking water (to European standards), since November 2019. This is the equivalent of 12 million 500mL plastic water bottles. The PAqua 1000D-2 has been trialled at a variety of locations in Europe by Portsmouth Aqua Ltd abstracting water from municipal and borehole sources (see Off-grid field testing section below).

Table 1. Biological quality of Raw water samples (taken from the modified water body) and Potable water (treated) from the PAqua 1000D-2 during the UWE Bristol trial. Results shown are the calculated mean from the independent ISO 17025 accredited laboratory reports. Values in red indicate exceedances with the acceptable limits for safe drinking water regulated by the Drinking Water Inspectorate.

| Water type | Raw water | Potable water | ||||

|---|---|---|---|---|---|---|

| UNIT | Mean | SD | Mean | SD | Accepted limit | |

| Plate count (2-day @ 37°C) | /mL | 367.13 | 228.46 | 0.125 | 0.35 | NS |

| Plate count (3-day @ 22°C) | /mL | 1704.00 | 753.47 | 2.67 | 4.47 | NS |

| Coliform bacteria | /100mL | 138.22 | 150.17 | 0.00 | 0.00 | 0.00 |

| Escherichia coli | /100mL | 76.89 | 57.92 | 0.00 | 0.00 | 0.00 |

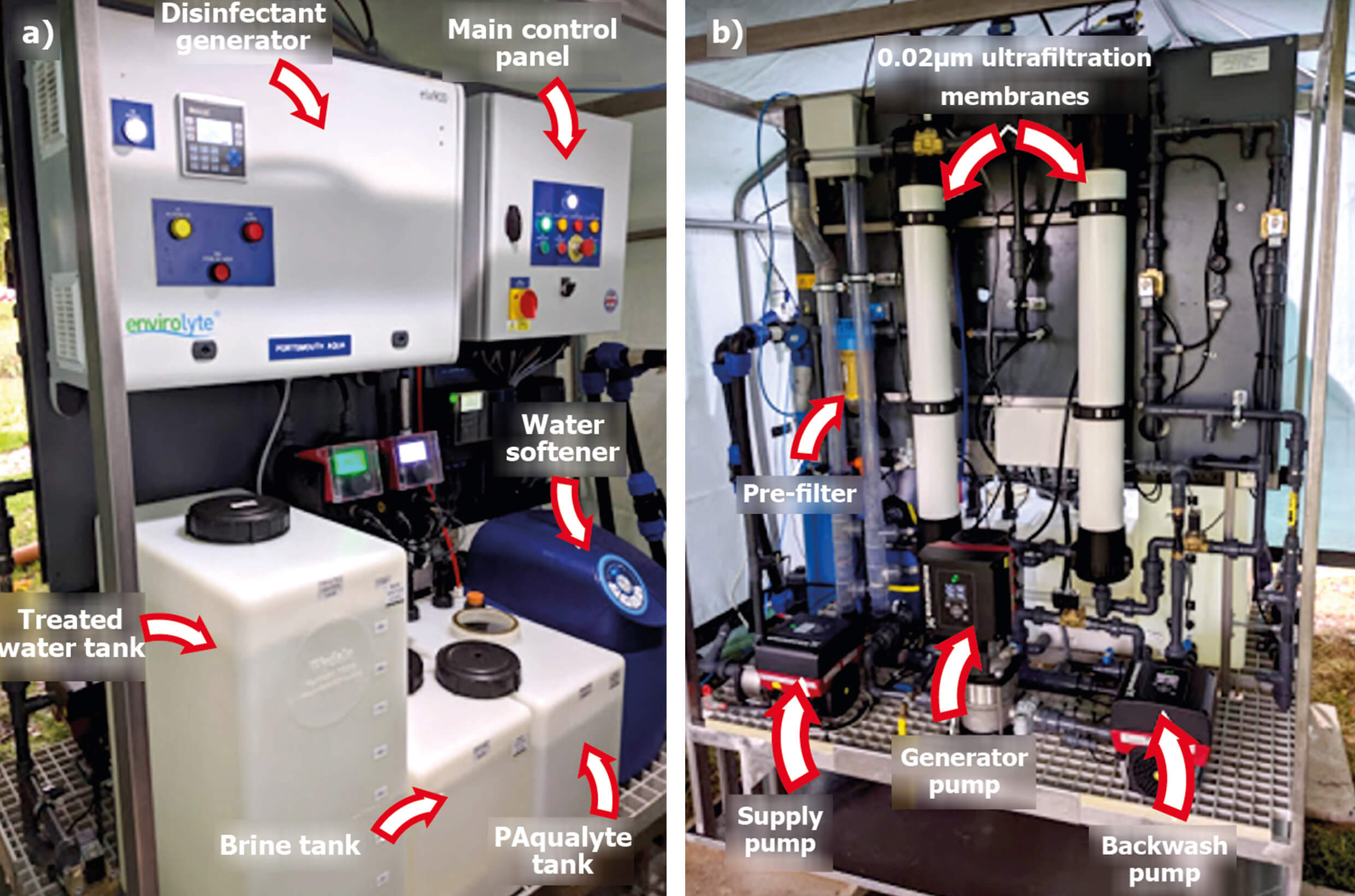

Figure 4. Left The PAqua 1000D-2 decentralised drinking water treatment system developed by Portsmouth Aviation and the University of the West of England, Bristol. Right Images of the PAqua 1000D-2 water purification unit: a) the front view of the units with disinfectant generator (ELA-900, Envirolyte® Group, Estonia), main power control panels, water, brine and PAqualyte tanks, and water softener; b) the rear view of the unit with the pre-filter, Inge (DuPont de Nemours, Inc., USA) ultrafiltration membranes, and supply, generator and backwash pumps (Grundfos, Denmark).

Off-Grid Field Testing

Based upon the field trials conducted at UWE, Bristol the operational systems of the PAqua 1000D-2 are now well understood. The PAqua 1000D-2 system was initially deployed in the zero carbon village of Icaros (Karystos, Greece). The technology platform was a desirable solution for Icaros due to the ability of the system to produce high quality treated water without the need for large-scale infrastructure and other consumables. This installation demonstrated the ability of the system to be powered using solar energy, alongside real-time remote monitoring via the mobile network. The borehole water available to the village was not suitable for human consumption due to biological and heavy metal contamination. After the installation of the PAqua 1000D-2, the newly treated water supply accomplished the accreditation of ISO 9001:2015. This accreditation, alongside the continued successful performance of the system, has led to the recommendation of its use by the Mayor of Kyriakos, Air-Marshall General Geroulis. The efficiency and effectiveness of the PAqua 1000D-2 has been further demonstrated by its recent successful deployment at Leamna Hospital in Craiova, Romania. The raw water here failed on both biological (coliform and heterotrophic bacteria) and physicochemical parameters, as a result of high ammonium and water hardness. Post-treatment by the PAqua 1000D-2, the water in the hospital (sampled at any point in the localised distribution network) is now biologically and physicochemically safe for drinking in line with European regulatory standards. In light of the COVID-19 Pandemic, the hospital is now looking to use the electrochemically produced stabilised HOCl (PAqualyte disinfectant an accredited bactericidal and virucidal product), that is produced as part of the water treatment platform, to provide local and on demand disinfectant.

This system is now fully compliant and commercially available from Portsmouth Aviation Portsmouth Aqua and future deployments through Europe and India are planned during 2021/2022.

This work was partially funded by the Natural Environment Research Council [Grant NE/R003106/1]

References

Clasen, T. and Edmondson, P. (2006) Sodium dichloroisocyanurate (NaDCC) tablets as an alternative to sodium hypochlorite for the routine treatment of drinking water at the household level. International Journal of Hygiene and Environmental Health. 209 (2), pp. 173–181.

Clayton, G.E., Thorn, R.M.S. and Reynolds, D.M. (2019a) Comparison of Trihalomethane Formation Using Chlorine-Based Disinfectants Within a Model System; Applications Within Point-of-Use Drinking Water Treatment. Frontiers in Environmental Science. 7 pp. 35.

Clayton, G.E., Thorn, R.M.S. and Reynolds, D.M. (2019b) Development of a novel off-grid drinking water production system integrating electrochemically activated solutions and ultrafiltration membranes. Journal of Water Process Engineering. 30.

Reynolds, D., Thorn, R., Fox, B. and Hlanabeza, E. (2015) Off-Grid Production of Drinking Water. Waterline: The Journal of the Water Management Society. Autumn pp. 14–15.

Robinson, G., Thorn, R. and Reynolds, D. (2013) The effect of long-term storage on the physiochemical and bactericidal properties of electrochemically activated solutions. International Journal of Molecular Sciences. 14 pp. 457–469.

Robinson, G.M., Lee, S.W.-H., Greenman, J., Salisbury, V.C. and Reynolds, D.M. (2010) Evaluation of the efficacy of electrochemically activated solutions against nosocomial pathogens and bacterial endospores. Letters in Applied Microbiology. 50 pp. 289–294.

Thorn, R.M.S., Lee, S.W.H., Robinson, G.M., Greenman, J. and Reynolds, D.M. (2012) Electrochemically activated solutions: evidence for antimicrobial efficacy and applications in healthcare environments. European journal of clinical microbiology & infectious diseases: official publication of the European Society of Clinical Microbiology [online]. 31 (5), pp. 641–653.

United Nations (2020) SDG Goal 6| Department of Economic and Social Affairs.

World Bank (2020) People using safely managed drinking water services (% of population).

World Health Organization and UNICEF (2017) Progress on Drinking Water, Sanitation and Hygiene Update and SDG Baselines.