As featured in waterline Spring 2018

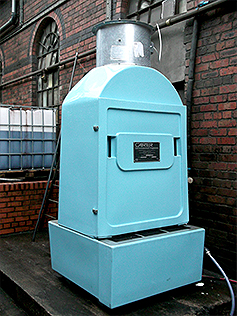

Materials Of Construction of Evaporative Coolers & Condensers

Colin Brown,

Carter Environmental Engineers

Taking into account the many considerations prospective duty holders have when deciding on the type of evaporative cooling and condenser equipment they should purchase, most will focus on how much will it cost to buy and will it fit the space they have available to site the unit?

The next consideration will be which material of construction will be used for the cooler and how long will the unit be expected to last? This type of equipment can be obtained in galvanised steel, painted or exotic coated mild steel, various grades of stainless steel and GRP all of which will have their merits but also some potential downsides.

All of these materials then have to be matched against the environment the cooler will be sited in, frequency of use, the application they serve and also the quality of the make-up water available. All of these factors should be taken into account when deciding which material of construction should be favoured but also and equally as important is the type of water treatment to be implemented. Indeed this is a consideration that will crop up periodically as water treatment contracts will come up for review and renewal throughout the lifetime of the cooler. However new treatment suppliers may not be as vigilant as to the original materials of construction of the cooler (as well as its internals) and the system possibly focusing more on their own standard water treatment kit and chemicals?

The selection of the shell and base tank material in particular are crucial to maintaining the unit’s hydraulic integrity throughout its working life. There are accounts of coated and galvanised steel coolers where corrosion has occurred which has eventually led to water leaks. This is a critical factor when deciding the material of construction of the unit as repairs to the structure in this scenario are costly and at a cost of downtime incurred to carry out the corrective action.

The overall cocktail of the all of the above will have a direct effect on the control of corrosion, scale and bacteria within the system and the cooler. In addition, and many consider just to be as important, is the ability of the cooler to provide the benefit of its original intention, i.e. to reject heat by evaporative cooling but at the same time remaining to be a safe item of working plant equipment.

Equally as important is the type and materials used for the cooler internal components such as heat transfer pack and drift eliminators as these will be a major consideration for the ongoing efficient operation of the unit. This focuses attention on the required cleaning process to keep these parts in a maximum efficient condition and how and when they and the tower may be cleaned. There are many cases where these internal components have been swapped out without due consideration to maintaining design capacities causing reductions in cooling and drift elimination efficiency as well as becoming problematic with fouling of scale and bacteria.

The “long game” view needs to be taken when deciding on purchasing this type of plant equipment and the material of construction to be used as the initial purchase cost can be deemed a short sighted view when considering the on costs you may be leaving yourself wide open for corrective actions at a later date.