As featured in waterline Spring 2020

SAMPLE MATRIX TYPES

– WHY DOES IT MATTER TO ME?

Nick Barsby, ADEY

What’s a matrix type?

A matrix is the specific type of a sample; for instance a type of sample is a water, but this can cover a wide range of matrix types, from Drinking Water through to Untreated Sewage.

What do UKAS say?

Accredited organisations (laboratories) will be expected to have sufficient validation data to demonstrate the capability of the method for the matrices detailed on their schedule of accreditation. Prior to the testing or sampling, and during contract review, the accredited organisation (laboratory) should establish that their methods/validation data match those for the specified matrix to be tested and are suitable for their customers’ specific requirements.

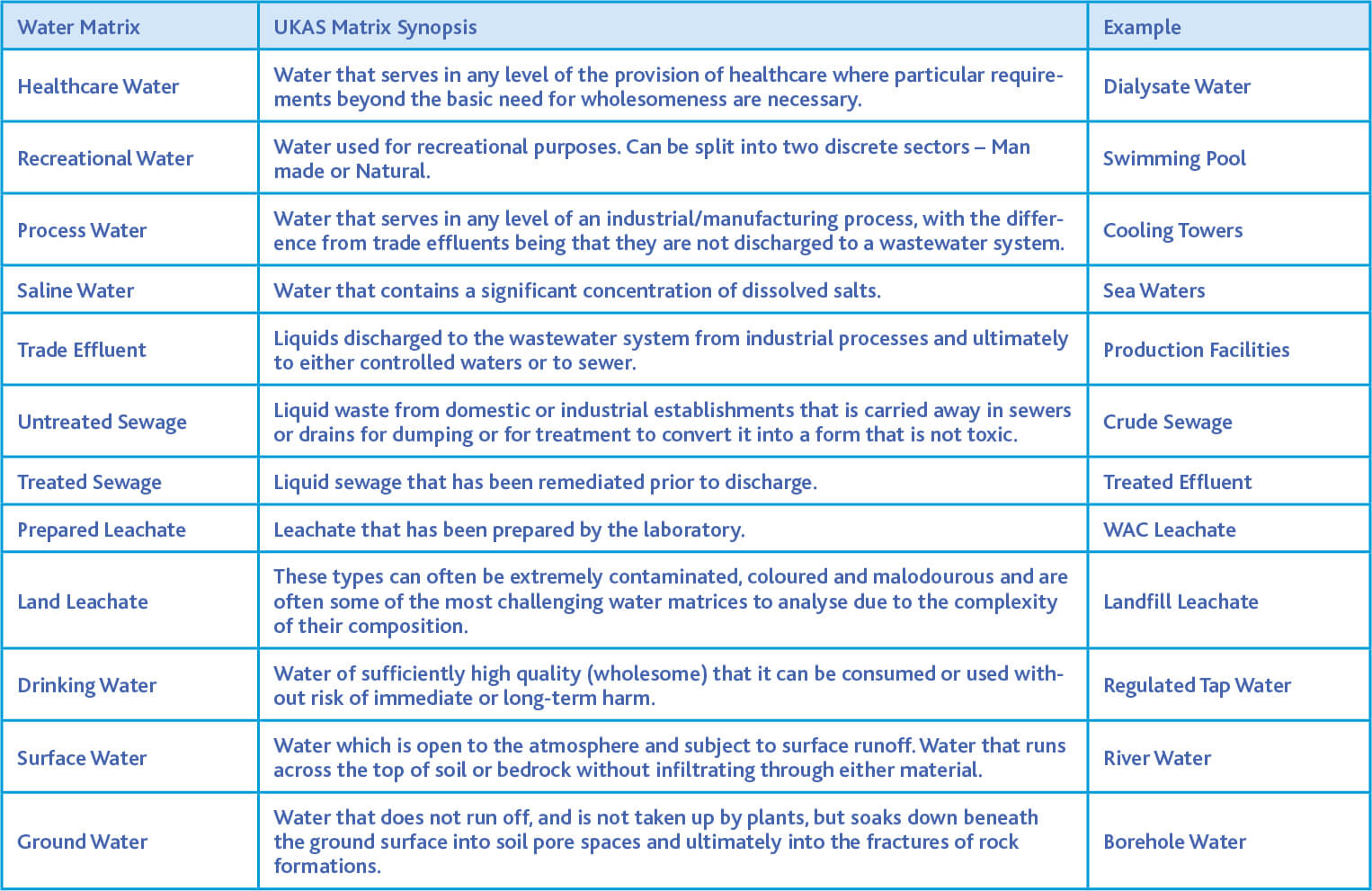

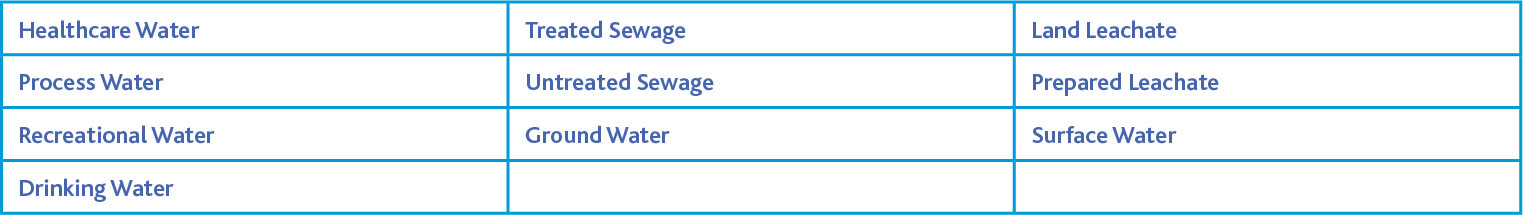

What are the UKAS Sample Matrix Types?

In May 2019 UKAS produced an updated list of sample matrix types that laboratories can claim accreditation against, these are:

Do I need to tell the laboratory my sample matrix?

Yes! The matrix is a critical part of the sample submission and testing process. This should be clarified at the quotation stage to ensure that the laboratory can process the samples, or find an appropriate subcontractor (if applicable).

Why is it important?

Matrix type is important for numerous reasons.

When a laboratory performs a validation study for their UKAS accreditation they do this against specific matrix types and as part of this UKAS submission the laboratory provide precision, bias and uncertainty of measurement data. This forms part of the accreditation process.

If a laboratory were to process a Treated Sewage sample on a Drinking Water method it would have significant implications on the original sample and could lead to damage to the analytical instrument, carryover contamination or breaches of Quality Control data.

What happens if I submit a sample matrix that’s not accredited?

If you submit a sample to a laboratory with a matrix that they are not accredited for then your test result will not hold UKAS accreditation. The laboratory could still provide a result for this matrix type, but the accuracy of this result could be affected.

Why are UKAS introducing Sample Matrix Types?

Laboratories have always had specific methods for specific tests and types of samples. The labs have also held accreditation against certain matrices. The change to customer requirements on matrix type has been driven to improve the end user’s data set.

In the past a laboratory could have attained UKAS accreditation for Legionella on a Drinking Water and claimed UKAS accreditation for a wide range of Water types; even if the method was not fit for purpose. Now, with Sample Matrix level accreditation and reporting, labs can only claim accreditation against sample matrix types they have been validated against.

The change means that end users can have greater confidence in the data that the analytical laboratory provides, even if it does place an additional burden on the Water Treatment company.

When did sample matrix types become important to UKAS?

Every year UKAS audit the laboratory and review how they are performing against the ISO 17025 standard. As part of the 2017 update to the ISO it’s now even more critical to make sure that clients of laboratories understand the implications of applying the right test to the right type of matrix.

UKAS issued a proposed set of sample matrix types in June 2014 through a Technical Guidance Bulletin; from this point all laboratories had a reference point to “standard” water matrix types. This Guidance has been revised in May 2019 with the addition of a Healthcare matrix for hospital specific tests, such as Dialysate Waters, Endoscope waters and the like.

How do I know what Matrix type my sample is?

UKAS have provided a useful reference guide to sample matrix types that can be found below; if you are unsure about the classification of your matrix type then speak to your laboratory before submitting samples.