As featured in waterline Spring 2018

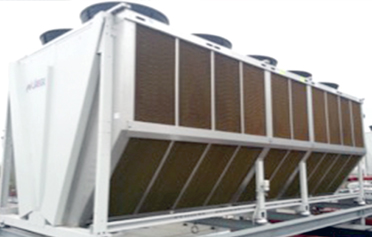

The Dry Wet Cooler v Cooling Tower Question

Colin Brown,

Carter Environmental Engineers

Waterline Guest Editors: this is a new feature that will hopefully introduce different topics into the pages of this journal. Colin Brown, a longstanding member of Council and the Chairman Elect, has taken on the the first Guest Editorship. You will find three articles by Colin within these pages that we hope you will find interesting and informative.

It has been a couple of years since the guidance notes on dry wet coolers (adiabatics , hybrids etc) prepared by WMSOC were accepted by the HSE and are now openly referred to when visitors to the HSE website are making queries on the suitability of dry wet coolers to replace evaporative cooling towers.

The usual remark when considering a dry wet cooler is that the user wants it to achieve the same re-cooled water temperature as their existing cooling tower all year round. In many cases this will be possible to achieve if the target re-cooled water temperature is around 26 deg C or above.

Once the design parameters are known and a dry wet cooler can be thermally acceptable, the next consideration is the space available to site the unit which invariably will take up considerably more space than a comparative cooling tower. Once this obstacle has been ticked off, the next focus of attention is with regard to noise and absorbed power and can the location on site accommodate these fan change implications?

The next step and probably the most important is the control measures required to operate the dry wet unit safely but just as importantly to maintain its maximum ability to dissipate process heat by the prevention of scale and bacteria proliferation on the unit coil matrix and secondary water distribution circuit. One location when compared to another may take on different operational issues dependent on the quality of secondary cooling water available as well as system and site impurity additions to the surrounding air and water sources.

The annual operation of the dry wet unit will also dictate when the “wet” side of the cooling process will be out of operation. During this period (normally between late October and mid-March in the UK) consideration should be given to the draining down of the water supply to the “wet” side of the unit and making safe until its use is required again in the Spring. This could be in the form of a total strip down as well as a pre-planned chlorination to protect the cooler and the water supply line, all subject to the system risk assessment.

These types of dry wet systems are growing in popularity and most provide the desired cooling at the design conditions through correct control measure design and provision. Yet there are dry wet systems in use which have no or little consideration to sufficient control measures and may become the focus of attention by the HSE as the number of these units continues to grow.

Hybrid dry cooler